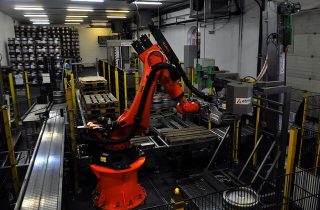

Palletization a depalletization of KEGs

Top beer needs top technology.

Customer:

Family brewery BERNARD a.s.

Customer description:

Family brewery BERNARD in Humpolec has reached much success and every year, there are more prestige valuations. You can meet the brand BERNARD not only in the CZECH Republic, but in many other countries. In year 2009, the production of brewery exceeded the border 200 thousand hl of alcoholic and nonalcoholic beer.

Reqiurements of the customer:

Modernization and automation of the beginning and the end of the filling line of KEG barrels with performance of 300 barrels per hour.

The intention of brewery was to obtain the most up to date technology for palletisation and depalletisation of KEG barrels. The technology had to be able to unstack pallets, do fitting control and uncapping of barrel on the depalletisation side. On the palletisation side, the requirement was for testing fitting tightness before capping, capping barrels, palletising of barrels. Part of palletisation is fixation of barrels on the pallet, application of labels A5, stacking of pallets. For this requirement, the design of palletisation of barrels with the use of industrial robot suited best.

Our solution

We used a pair of six axes industrial robots.

Palletisation robot, except palletisation itself, makes the fitting tightness control , capping of the barrel and their turn. The biggest advantage of this solution is economy and minimal built up space.

Company Atrima designed efficient and technically unique solution of palletisation with the use of industry robot. The result is 100% technological efficiency of palletisation, trouble free run and work safety.

KR 240 R 2500 prime (KR QUANTEC prime) Type KR 240 R 2500 prime is specially optimased for maximum space saving, density of installation and differant possibilities of assembly. It has load limit to 240 kg and reach up to 2 500 mm.

Date of realization

11/03/2016